Shop Air Cutting

The cost-effective alternative in laser cutting

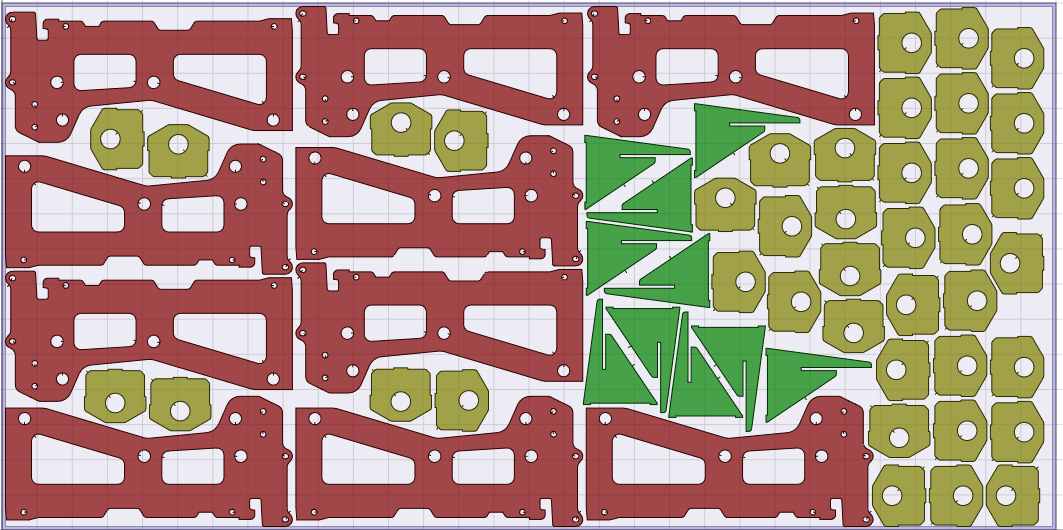

Compressed air can be used as an alternative to the standard cutting gases nitrogen and oxygen. The main benefit of this application is in terms of cost of operation. Shop air is considerably cheaper than nitrogen, whilst having a similar parts output.

Benefits:

- Lower cost per part

- Easy availability of shop air

- Especially beneficial for aluminum processing

Note: Cost of operations contains investment costs, depreciation, interest rates, floor space costs, electrical consumption, gas consumption and service costs and spare & ware part costs.